Casting Materials Guide

Here, we introduce some of the key characteristics of the main materials we use for casting parts.

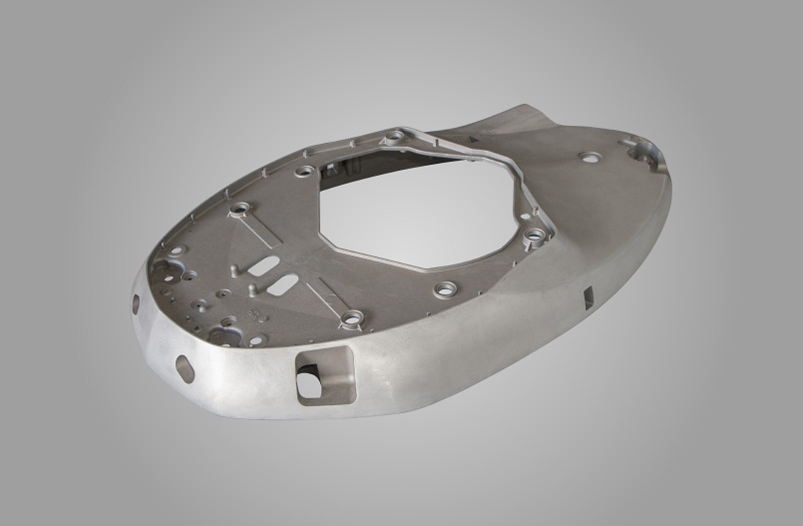

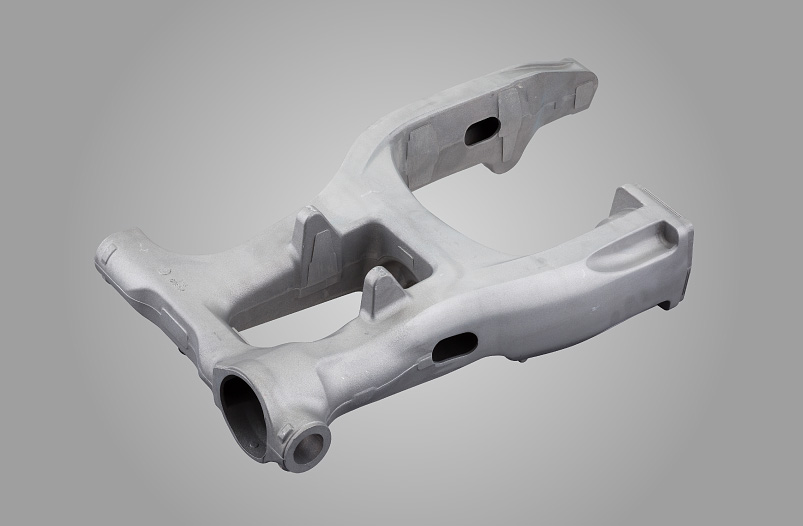

ADC3

An Al-Si-Mg alloy for die-casting, it is well-suited to elongation and has excellent corrosion resistance, heat resistance, etc.

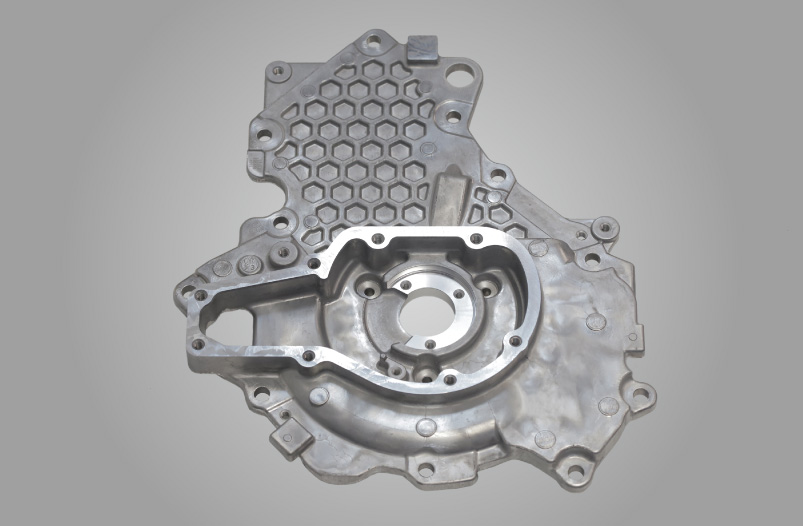

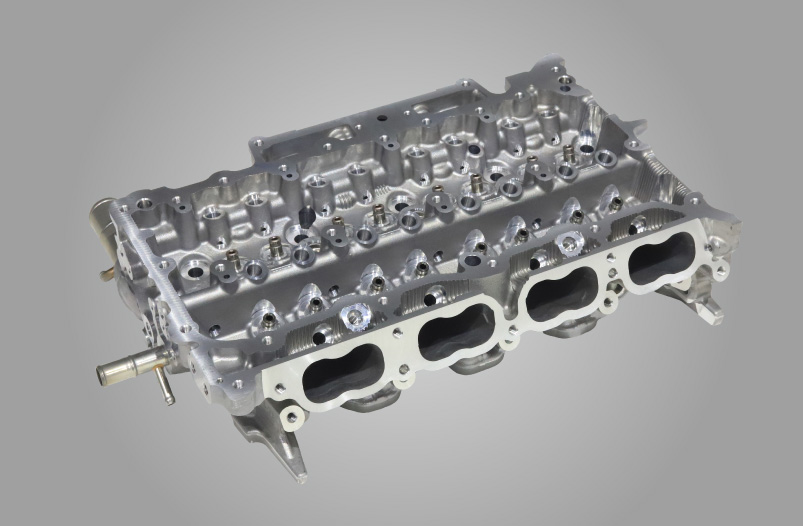

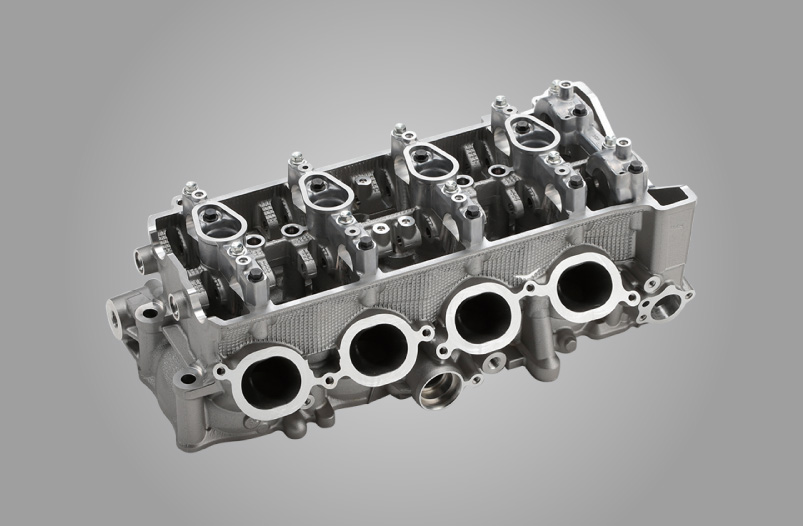

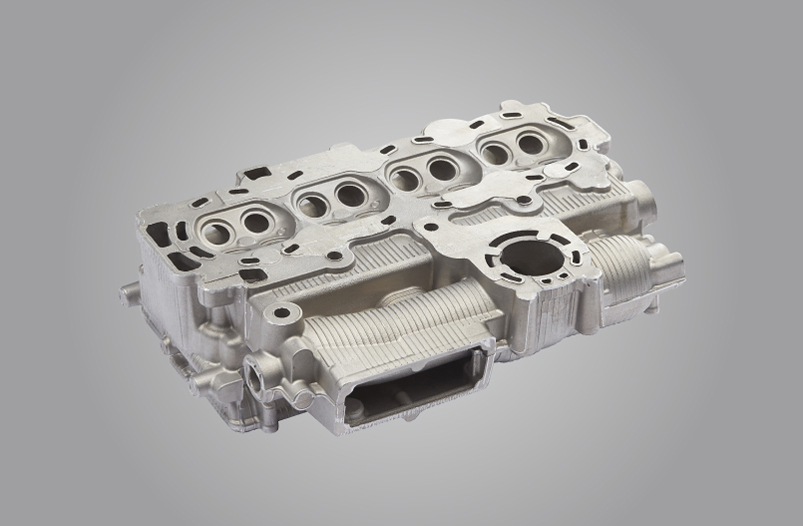

Parts using ADC3

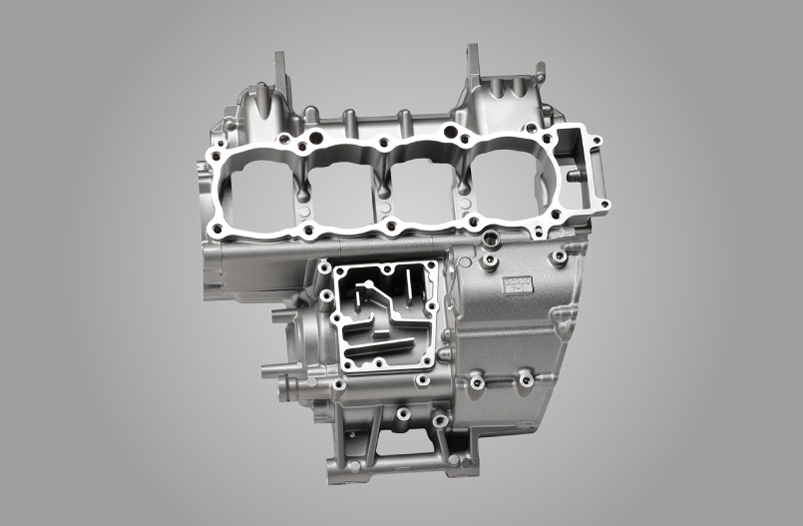

ADC12

An Al-Si-Cu alloy for die-casting, it is the most commonly used material.

Parts using ADC12

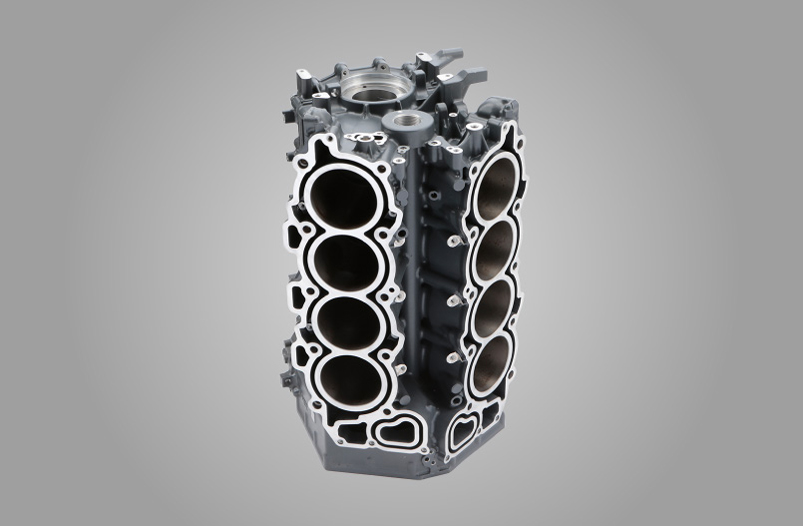

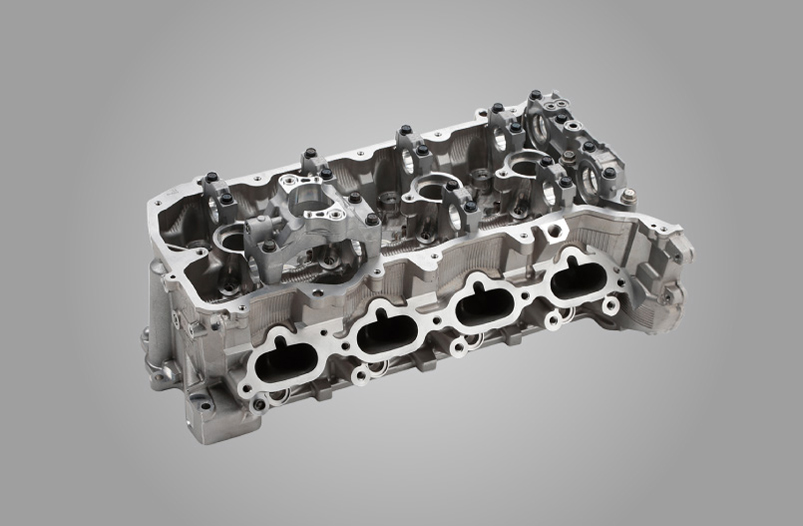

AC2B

An Al-Cu-Si alloy for mold casting, it is the most commonly used material.

Parts using AC2B

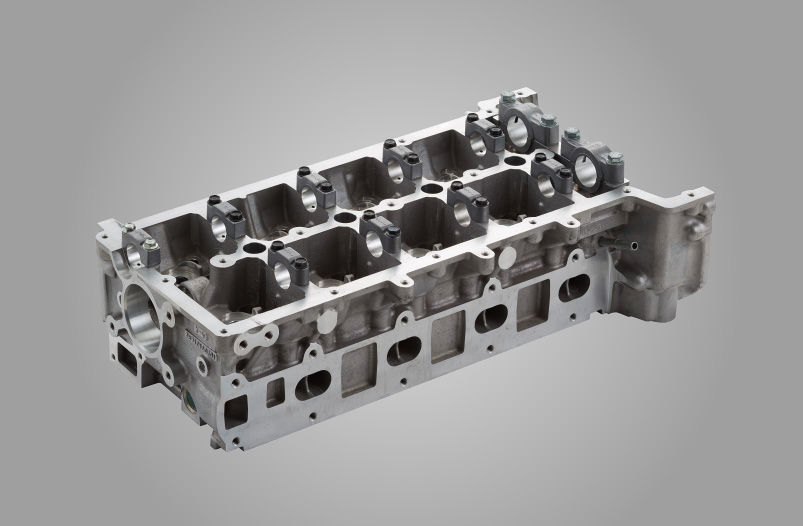

AC4B

An Al-Si-Cu alloy for mold casting, it is the most commonly used material.

Parts using AC4B

AC4C

An Al-Si-Mg alloy for mold casting, it is well-suited to elongation and has excellent corrosion resistance, heat resistance, etc.

Parts using AC4C

AC4CH

An Al-Si-Mg alloy for mold casting, it has standout elongation qualities, but also excellent corrosion and heat resistance.

Parts using AC4CH

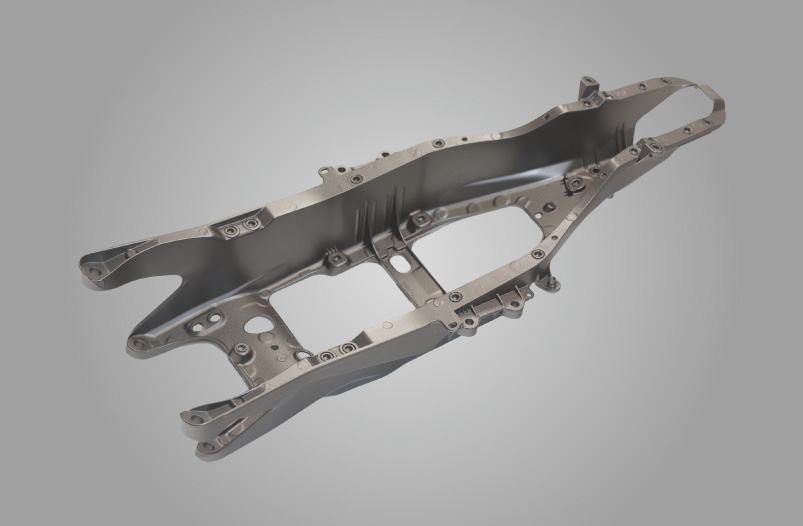

MD2B(AM60)

An alloy for magnesium casting, it is well-suited to elongation and has excellent strength, etc.

Parts using MD2B(AM60)

MD1D(AZ91)

An alloy for magnesium casting, it is the most commonly used material.

Parts using MD1D(AZ91)

Useful Information

Top