Multi-axis controllers with advanced functions RCX221/RCX222

Introduces the multi-axis controllers, RCX series.

RCX221 / RCX2221 to 2 axis controller

Feature

01Supports all YAMAHA robot models

The RCX series supports all YAMAHA robot models such as the PHASER, FLIP-X and XY-X. It makes most types of applications possible since single-axis (FLIP-X/PHASER) and Cartesian robot can be used in any desired combination (not including some small single-axis robots).

02Complete absolute specs

The RCX uses complete absolute specifications so of course no origin return is needed when the power is turned on. It also supports incremental specifications on a completely identical system (The PHASER series utilizes a magnetic scale and supports semi-absolute or incremental specifications.)

03Longer extended absolute data backup time

Making an energy-saving backup circuit has drastically extended the retention time for absolute position data with no power applied. Ordinary model backup time was a maximum of 1 month has now been boosted to 1 year. Current position information can now be monitored during long vacations, equipment storage, or even during transport, and origin return is not needed when power is restored. This allows quick and easy production startups.

04Area check output function

This function provides an output signal when the robot enters a preset area. Up to four areas can be specified.

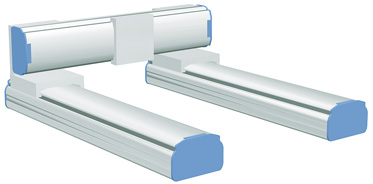

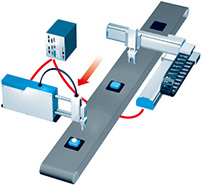

05Dual-synchronous drive

Equipped with the dual drive function to control 2 axis in synchronization, which is of effective use for carrying heavy items and long stroke operation with the Cartesian robot. This function enables good use of high speed, acceleration/ deceleration features of the YAMAHA robots.

- Note.

- For the dual drive function, custom order arrangement is required. For more information, contact YAMAHA.

Dual-synchronous drive example.

06Double-carrier anti-collision control function

Collisions between carriers when using double-carriages can be prevented by a control function within the controller. Former collision prevention measures such as zone judgments or external sensors are no longer needed so double-carriers are now easier to use than ever before.

073D circular interpolation control

2D and 3D linear and circular interpolation ARC control are possible, making the RCX141 controller ideal for sealing work, etc. (3-dimensional interpolation is only available on the RCX340)

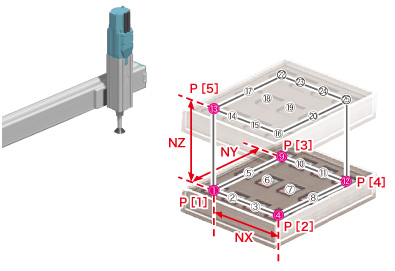

08Palletizing function

This function can easily define a maximum of 20 types of pallets by just entering the teaching points for the 4 corner positions on the pallet. Entering teaching points along the height allows handling cubic pallets. Specify the defined pallet No. and execute the movement command to perform palletizing. The program can execute various actions such as 1 point → pallet, pallet → 1 point, pallet → pallet, etc.

09Hand definition

This function operates the robot based on coordinates when the tool tip has been installed in the tip of the robot shaft in an offset position. This is especially effective during tool rotation on SCARA robots and robots with rotating shafts.

10Shift coordinates

A deviation or offset might occur in the coordinates during service tasks such as robot reinstallation or replacement. In those cases using the coordinates can be corrected by using the shift coordinate function so point data can be utilized without having to make changes and there is no need for reteaching.

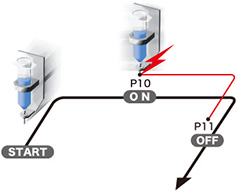

11Passing point output control

This function can turn general outputs ON or OFF at specified points so operation can continue with no stops along an axis during interpolation tasks. This outputs a spray ON or OFF signal while still operating on an axis during sealing to allow stable and smooth coating of sealant.

12Torque limiting drive

The motor torque can be limited during grasping and press-fitting operations.

13Multitask function

This function executes multiple tasks (up to eight tasks) Multiple tasks will switch with the timesharing method. However, a priority can be assigned to each task. This priority can also be changed while tasks are running. The multitask function simplifies the entire system窶冱 control configuration and also improves the operation efficiency.

Task scheduling

14Sequence program

In addition to the standard tasks, a task to control input/output (parallel, serial, memory, timer) can be executed independently. As the sequence program is effective in the manual mode as well, it is usable to construct the safety system linked with the peripheral equipment.

152-robot control

Assigning 2 robot units as main and sub allows them to be simultaneously operated by 1 controller unit. Combining this with multi-tasking allows 1 controller unit to link 2 robot units in a smooth, sophisticated operation.

16Additional axis function "YC-Link"

Using an optional YC-Link, the RCX series controller and SR1 series single axis controller can be linked easily. If necessary, by linking some controllers, it is possible to control up to 8 axes (Max. 6 axes for simultaneous control).

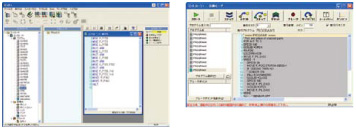

17Full support software: VIP+

VIP+ is an easy to operate application software that makes it easy to visually understand tasks including robot operation, program writing and edit, and point teaching. The user interface has been vastly improved compared to previous support software VIP and is now extremely easy to use.

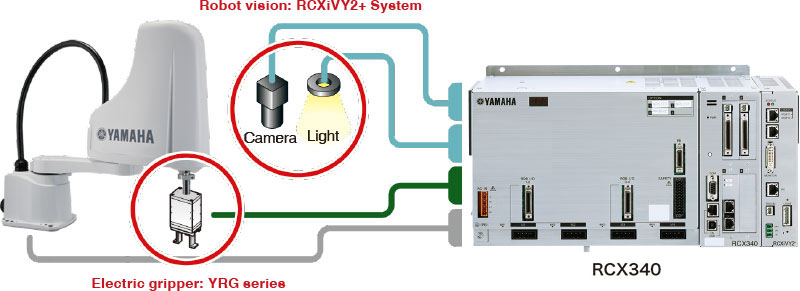

18Can be used with a "YRG series" electric gripper

All functions of a gripper can be controlled from one RCX340 controller. Setup and startup are very easy since no signal exchange with a PLC or host device is required.

Various data

- Support software VIP+(PLUS)Catalog (560KB)

- Programming box RPB/RPB-E Catalog (200KB)

- NETWORK catalog (174KB)

- Basic specifications (185KB)

- Part names / dimensions (208KB)

- Connector signals table (129KB)

- Example of input / output signal connection (129KB)

- Robot Language Table (194KB)

- Power capacity (129KB)

- Regenerative unit RG2 (208KB)

- Accessories and part options (280KB)

- Field network system with minimal wiring NETWORK (199KB)

- Ordering method (185KB)

Multi-axis controllers with advanced functions RCX221/RCX222

Related contents

- Cartesian robots

- A wide variety of Cartesian robots, XY-X series, with appropriate performance meeting the customers' needs.

- Multi robots

- Introduces the single-axis robot, multi-robot.

- Field Networks (RCX)

- Robot controller RCX series is applicable to the field networks CC-Link, DeviceNet, Profibus, Ethernet, EtherNet/IP.

- Cable

- Dimensional diagrams and model numbers of the robot cables, cable terminals, and connectors are available.

Robotics Operations

Sales & Marketing Section

FA Sales & Marketing Division

127 Toyooka, Kita-ku, Hamamatsu, Shizuoka 433-8103, Japan

Telephone 81-53-525-8350 /

Facsimile 81-53-525-8378